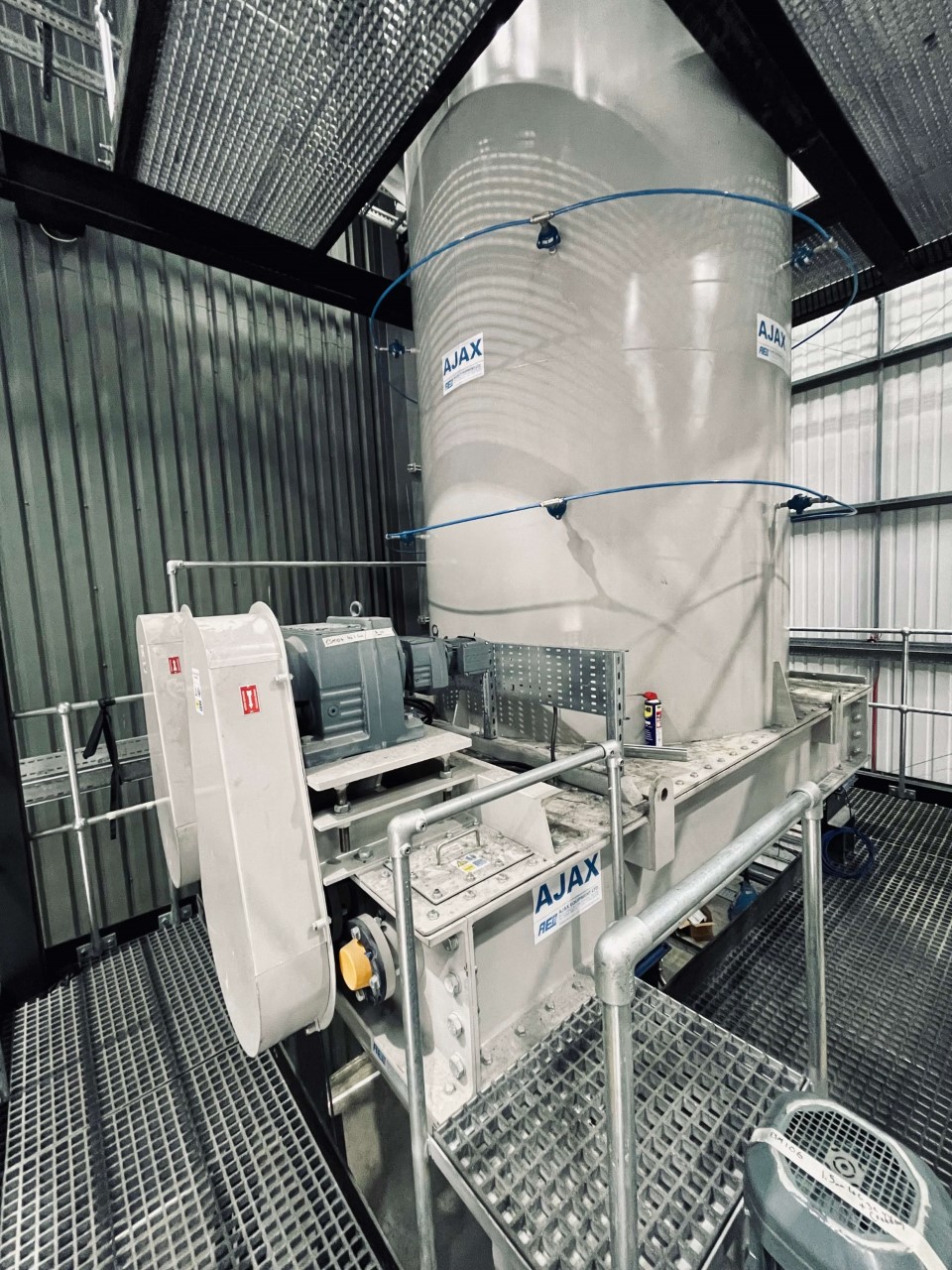

Double, triple and multiple screw feeders including 'live bottom' hoppers for handling powders the need wide inlents to prevent arching over narrow slots.

44 (0)1204 386723

sales@ajax.co.uk

sales@ajax.co.uk

Customer

Testimonials

Testimonials

Products

Page

Page

Solid News

Newsletters

Newsletters

Company

Brochures

Brochures