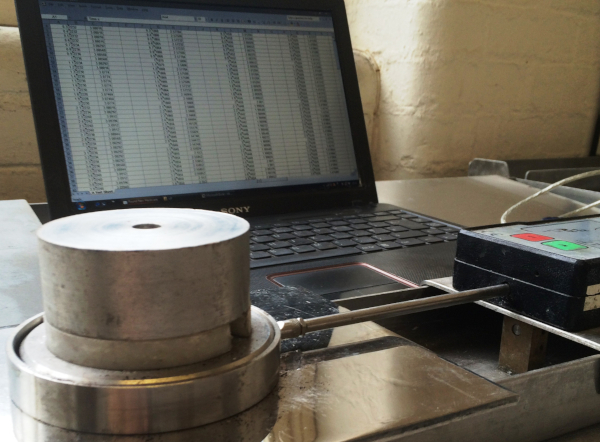

AJAX Vertical Shear Cell Test

1. Introduction.

This equipment, as shown in the 'in use' photograph opposite and the 'component detail' photograph later measures the force required to vertically shear a circular disc through a prepared sample of bulk material. The test is simple to undertake. When the sample is prepared to represent conditions relevant to a particular application, the value measured provides a means to indicate the orifice size through which gravity flow will be reliably initiated.

2. Background to Shear.

The resistance to the initiation of flow of a bulk material is dependent upon the nature of the material and the conditions to which it has been subjected. Once flow has started, the resistance of the material to sustain deformation loses its sensitivity to the condition it was in before flow commenced.

During flow, a bulk material will shear continuously in a condition termed 'critical state'; so named because there is a unique relationship between the stresses causing the shear and those acting at right angles to the shearing surface. If material in motion is brought gently to rest, it will restart flow in similar circumstances to those in which it was flowing.

Measuring the dynamic shear conditions in varying density conditions is the basis of the Jenike method of shear cell testing. This well proven technique incorporates a methodology for designing hoppers, but is has the drawbacks of requiring an extensive sequence of tests and demanding considerable expertise in its execution to secure useful and consistent results. This method is time consuming and expensive, and may be unnecessary for initial evaluation purposes, materials which do not present great difficulties or uncertainties, or for applications which do not call for sensitive results.

The Ajax Vertical Shear Cell is a simple, easy and economical way of providing a measure of the strength of a bulk material in a specific condition of compaction. The results reflect initial failure conditions of the static bulk, rather than the shear strength in continuous deformation found in flow situations. This is particularly relevant, as at the initiation of gravity flow, the strength of the material has to be overcome by the stresses developed as a consequence of the weight of the solid. It is important, therefore. to establish the strength of the material at the particular density of interest. This initial strength has various values, depending upon the conditions under which the material was brought to rest and the forces acting on it at the time it is required to 'fail'. For example, compaction conditions during the filling of a hopper are different from those pertaining after some contents have discharged. Conditions of compaction vary for many reasons and, therefore, there is more uncertainty about the conditions needed to promote flow than being able to continue flow once it has started.

Despite this aspect, or perhaps because of it, the vertical shear test offers an economical process for investigating flow potential of a bulk material of uncertain flow prospects. It is also useful for comparing how different samples of a material may behave, or how one material compares in flow potential with a reference product or with another bulk material of known behaviour. The test can be used as a comparative tool for quality control and for process assessment purposes, or to provide a guide to the size of orifice through which a bulk material will reliably commence to flow from a settled condition.

Material will span over an opening when the strength of the material is able to sustain the stresses imposed on it by the mechanics of the arch. The presence of an arch means that there is no material on the underside offering a supporting pressure, so the two conditions under which an arch will break down are when:

a. the 'unconfined failure strength' of the material exposed at the free underside surface is exceeded by the stresses in the arch, or,

b. when the shear strength of the ends of the arch are unable carry the vertical load of the mass which the arch supports.

It is this latter feature which the vertical shear cell addresses. To consider the stresses acting on the ends of the arch, the worst case is that of support from a flat surface such as with a flat-bottomed hopper with a hole or slot in the base. With a hole, the arch is three dimensional, in the form of a dome, whilst with a slot opening, the arch forms a simple, two dimensional, linear arch.

3. Basics of the Ajax Vertical Shear Cell Procedure.

Key to the representation of this test to a particular application is that the material sample tested is in a condition which reflects that achieved by the bulk solid in the outlet region for the application under consideration. The state of compaction achieved by the material in the stress conditions applicable in this region corresponds with the specific density attained by the material.

Therefore, density measurements are used as a reference basis on which to define the bulk material condition. The density value is important to reflect the load acting on the arch due to the material weight, but is an even more critical measure of the compacted condition which the material attains as this radically affects the strength with which the material resists shear stresses.

The first stage of preparing a sample for testing is to subject the material to a consolidating load similar to that which acts on the material in the hopper region near the outlet. This will prepare the strength conditions the bulk material attains in this sensitive location and also determines the density of the material in this condition.

The test must then capture the maximum load required to cause the sample to fail, which can be added to the weight of the portion of the sample contributing to the collapse to give the total load which caused the material to shear. Knowing the whole failure load and the area over which this way applied, the critical size for a dome or a simple arch can then be calculated.

4. Equipment Description

The equipment, whilst simple in design and use, is subject to redesign and improvement in line with new approaches and developments and comprises basic cells and instructions for evaluation purposes.

The standard Vertical Shear Cell comprises:

Shallow plastic test cell with filler disc, nom. 140 mm diameter x 32 mm deep filling ring, 32 mm deep.

Preparation bridge with compacting plunger for applying load.

Consolidating weights.