Powder Handling - Meeting the Pharmaceutical Manufacturing Challenge.

The demands of processing difficult to handle powders leave manufacturers of pharmaceutical equipment with a difficult balancing act to meet. One the one hand there is the need to provide very high levels of containment commensurate with the manufacture of increasingly potent active pharmaceutical ingredients (APIs) while on the other hand the equipment also has to offer reliable, on demand, discharge of materials that have poor flow characteristics. The risks of blockages cannot be countenanced as production interruptions; material spoilage and exposing operators to hazards are all to be strictly avoided.

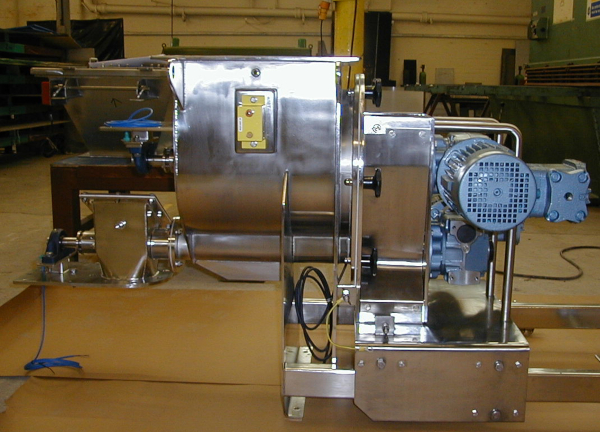

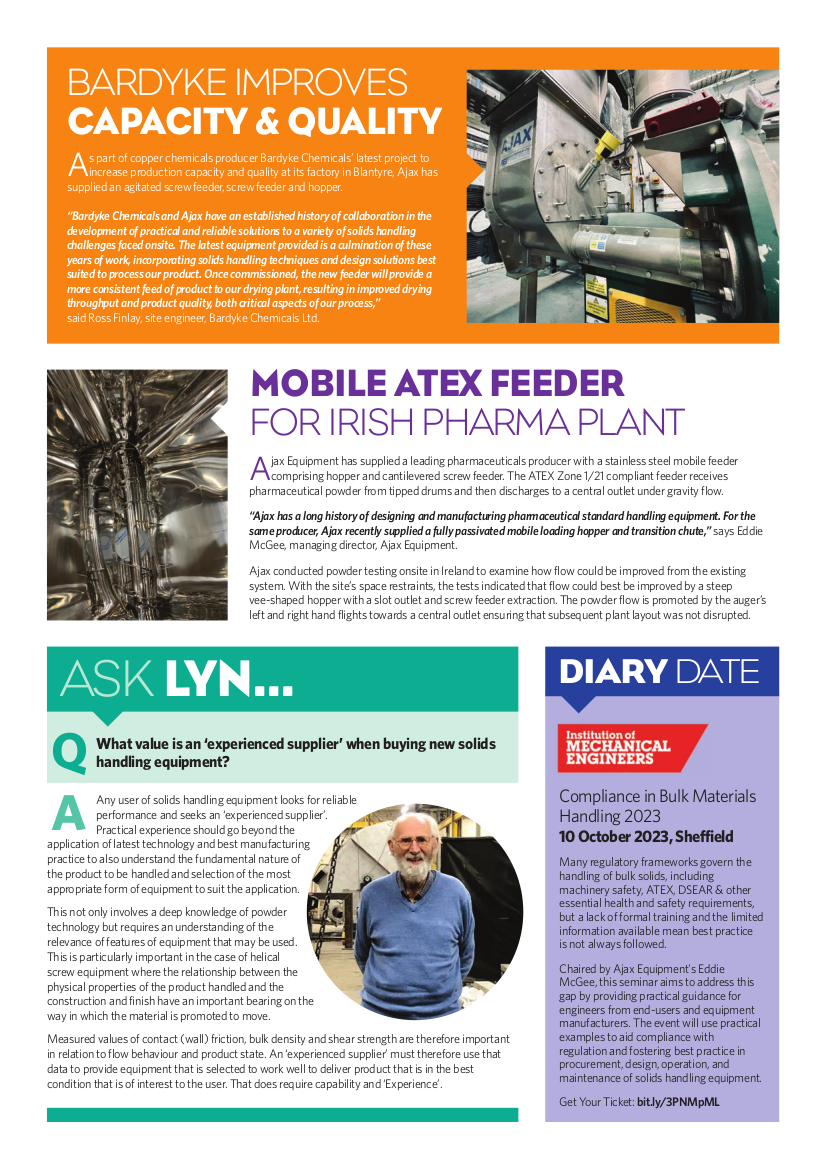

Just such a challenge faced powder handling specialist Ajax Equipment when manufacturing a hopper and screw feeder for leading powder processing equipment supplier Hosokawa Micron. In this instance the equipment also required clean-in-place and steam sterilisation-in-place, and, unusually, had to meet the combined requirements of ATEX and the Pressure Equipment Directive (PED).

The Ajax Approach

From a powder handling perspective, Ajax Equipment’s approach was to treat the hopper and screw feeder as a single construction from which, in this case, powder is fed to a jet mill for further processing. The pharmaceutical manufacturer had commissioned independent testing of a variety of milled and un-milled powders for their wall friction, bridging and bulk density characteristics. These indicated that agitation of the powder produced the best material condition for handling both milled and un-milled powders. Drawing on its expertise in powder handling, Ajax Equipment also interpreted the flow characteristics of the material to design an agitator to sweep close to the walls of the hopper, eliminating the risk of bridging, and ensuring smooth, reliable powder flow to give stable in-feed to the mill.

Ajax Screw Feeder Design

Using the powder handling analysis data, Ajax was also able to tackle the most difficult part of the project – overcoming the poor flow characteristics of the powder to ensure a reliable and controlled feed from the agitator via the screw to the client’s milling machine. The screw feeder had to meter pharmaceutical powder out of the hopper at a variable rate of between 20 to 100 Kg / hour. Ajax Equipment designed a state-of-the-art volumetric screw feeder with a stepped shaft and variable pitch, to pick up material progressively from the full length of the agitated hopper outlet, to provide a consistent feed rate to the mill. The agitator and screw feeder drives are controlled by separate invertors to maximise co-ordination between agitation and screw feed for optimum powder discharge.

SIP and CIP

To meet the stringent demands of steam-sterilisation in place, both the hopper and screw feeder are cleaned by steam at 1.5 bar with a temperature of 128 0C. The customer also imposed further demands by requiring the equipment to operate at a maximum operating temperature of 140 0C and to withstand an internal pressure of 4 bar. Furthermore the equipment also had to sustain a full vacuum.

Ultra-Hygienic Construction

All parts of the hopper and screw feeder are constructed of 316L stainless steel with internal surfaces mechanically polished and then electro polished to a finish of 0.3 microns. The hopper has a jacketed construction for insulation ensuring minimal heat loss to maintain temperature during the steam sterilisation procedure. To meet hygienic processing requirements, all internal surfaces are crack and crevice free. In addition all joints feature a modified ‘O’ ring flange joint profile which was specifically engineered by Ajax. This joint arrangement uses a combination of FDA compliant aseptic seals in PTFE, and silicone and encapsulated FEP for all access points and joints.

ATEX Rated

ATEX rating for pharmaceutical manufacturing equipment is commonplace. However in this case it is the vessel’s internal zone, which demands ATEX compliance with the equipment itself being positioned in a safe area. The hopper’s internal pressurised processing atmosphere is classed as hazardous and rated ATEX Zone 21 to a maximum surface temperature of 160 0C. This meant that mechanical features such as clearances between rotating parts and relative velocities require careful consideration.

Validation of Clean-ability

During the pre-commissioning stage of the hopper and feeder by the client, the assembly had to be exposed to acid and alkali reagents and cleaned with pharmaceutical quality water. The unit is then stripped down and swab tested to validate the cleanliness of the hopper and feeder after cleaning.

Once the pharmaceutical company is confident and assured of the effectiveness and repeatability of the cleaning regime, the vessel can then be used for a number of manufacturing campaigns using many different APIs without disassembly for cleaning between campaigns.

To further assist with maintenance, Ajax Equipment used a tri-clover clamp fitting at the top of the agitator’s ceramic coated shaft with PTFE lip seals and O-ring seal assembly. This allows the agitator to be dismantled without removing the drive shaft. Similarly the screw feeder contains a bespoke seal assembly such that the auger can be removed without disturbing the seals. The seals in both the hopper and feeder are fulfilling an important role in both preserving the pressure during cleaning as well as eliminating the risk of leaks.

Ensuring the seals assemblies are not disturbed during disassembly to gain access to shafts and the like is also important in preventing incorrect seal orientation errors during reassembly.

According to Mark Waters, director, Ajax Equipment, “Designing a screw feeder that ensures a reliable and stable feed rate, while avoiding blockages, for difficult to process API powders is where our expertise and experience makes the difference. High levels of containment and CIP are standard for pharmaceutical equipment. What made this project different were SSIP and the ATEX rating for the hopper’s internal atmosphere together with the need for complete disassembly of the hopper and screw feeder for validation testing during commissioning. We were able to draw on our wider engineering expertise to meet these requirements.”

For Iain Crosley, director, Hosokawa Micron Ltd, the Ajax Equipment approach produced an elegant piece of equipment while balancing the competing aims of reliable discharge, high levels of containment and ease of disassembly. “Ajax Equipment’s knowledge of powder processing is excellent and has given us a well designed agitated feeder that is able to meet the most demanding requirements of our pharmaceutical customer,”

For more information on AJAX's screw feeders please visit our

Screw Feeder page or call AJAX on 44 (0)1204 386723.