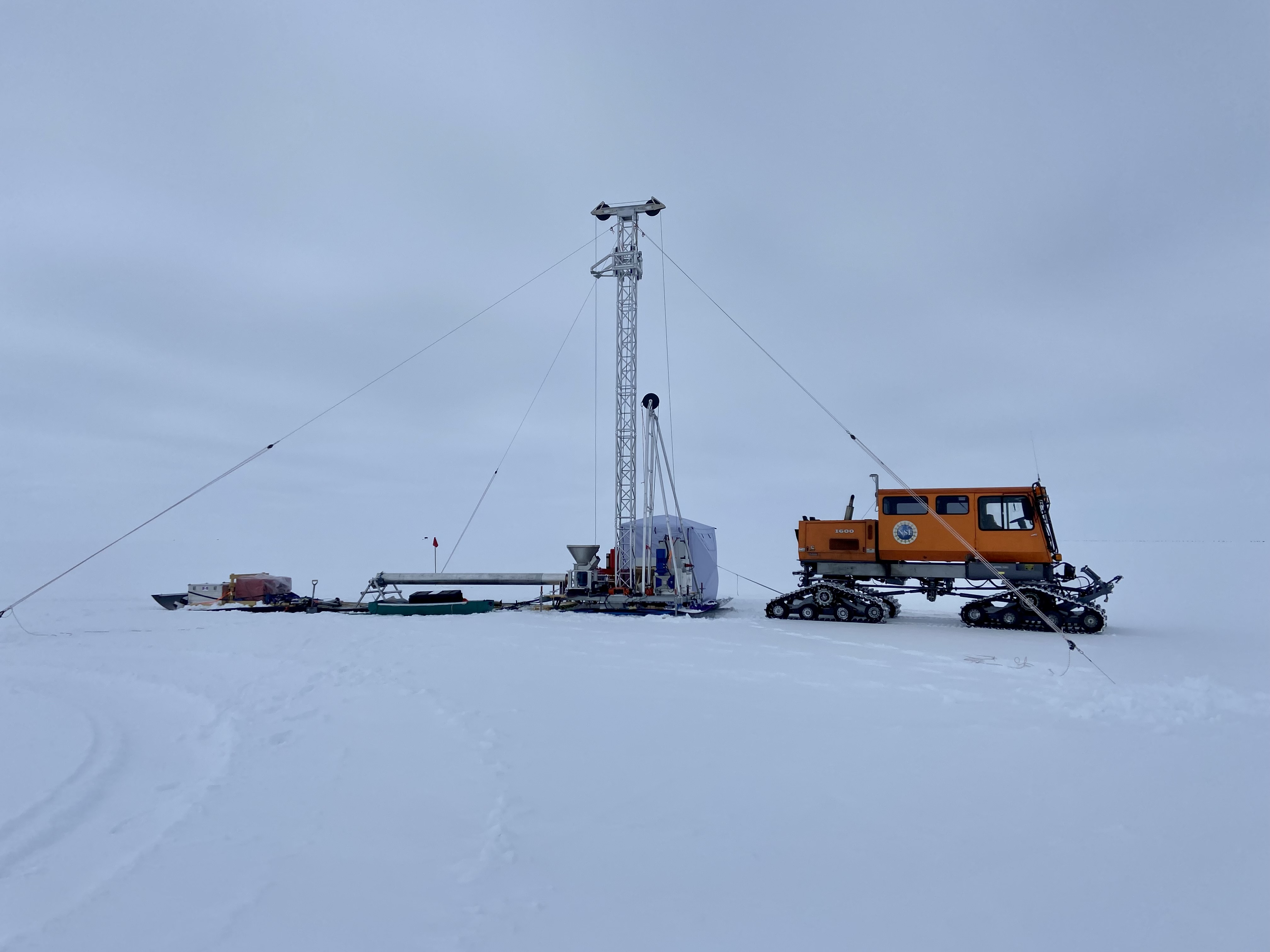

Ajax Inclined Twin Screw Feeder for Pork Rind Handling

Solids handling specialist, Ajax Equipment, has supplied Essentia Protein Solutions Ltd, a leading protein producer for the food processing industry, with a stainless steel hopper and inclined screw feeder to improve throughput, handling and inspection of pork rind at the company’s West Midlands, UK facility.

Pork rinds are discharged from the hopper into an inclined twin screw feeder and deposited onto a belt conveyor where they are subject to a visual inspection. The previous hopper geometry and screw design caused bridging, resulting in ‘all or nothing’ flow. In addition to overloading the large diameter single screw feeder, it also made inspection more difficult due to the sudden large volume of rinds on the inspection conveyor. The Ajax solution offers several processing advantages. The Ajax hopper features steep walls and a more generous outlet size that promotes material discharge, allowing pork material to flow into the screw feeder consistently. The design also takes account of the awkward aspect of changing the flow direction of a product that does not flow easily.

By utilising an Ajax twin screw feeder with large diameter screws and variable pitch geometry, the hopper extraction profile has improved as well as the ability to cope with variation in the size of pork rind. The feeder’s casing has a specialised profile to ensure effective transfer while allowing for covers to serve inspection and cleaning needs. The whole unit sits on a mobile framework to allow the machine to be relocated on site, away from the main production areas for cleaning and sanitizing.

On the project Paul Setchell, Factory Manager at Essentia Protein Solutions, said “Having worked with Ajax previously we knew they had the design expertise required and shared Essentia’s pride in attention to detail. Similarities in our approach made it easy to collaborate, bringing together our knowledge of the material and Ajax’s understanding of moving material”. Describing how the hopper and screw feeder have impacted the process Paul continued “The previous machine was unable to withstand the variation in material and consistently provide the throughput required, creating a bottleneck in the process. Since installing the new Ajax screw feeder we have reached the desired level of production, setting record levels of through-put in the process”.

The Ajax twin screw feeder includes several features to allow the equipment to be easily cleaned. In addition to being mounted on a mobile frame, the twin screw feeder also benefits from Ajax’s special hinged and counterbalanced covers which are interlocked to provide safety and security during cleaning. A drop down end plate arrangement also makes it easy to wash down and safety interlocks ensure operator safety.

For more information on AJAX's screw feeders please visit our

Screw Feeder page or call AJAX on 44 (0)1204 386723.