AJAX Cohesion Tester

1. Introduction.

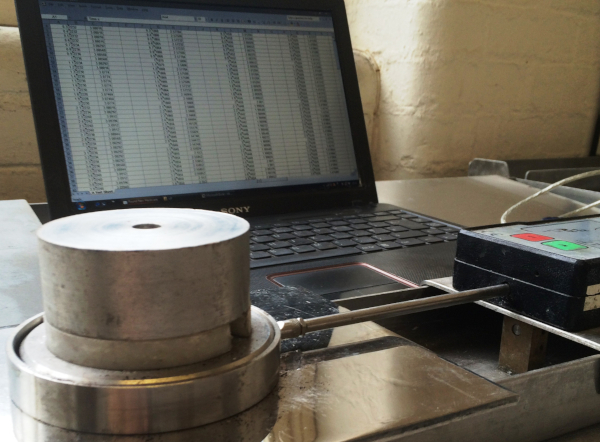

The equipment, as shown opposite, is designed to directly measure the cohesive strength of samples of powders in varied states of preparation, from lightly settled conditions to firm compacts.

2. Equipment Description

A stainless steel annular cell is carried in a light spindle in ball bearings. Torque is applied by means of screw extension of a null balanced low hysteresis coil spring operating through a pulley. A sensitive measure of the failure stress is given by a 'totalizing' counter mounted on the operating screw in conjunction with a calibration graph.

The equipment is mounted on a bench stand and is fitted with a screw height adjustment for offering the mechanism to the sample. A sensitive scale is included in the arrangement to allow vertical forces on the sample to be eliminated.

The full head can be reversed to enable the machine to be used in an over-hanging position if required. Preparation stands and sets of cells comprise:

Three sets of cell bases, each complete with filling ring and stainless steel compacting plunger with a guide bracket. The cell bases are marked with the tare weight and volume for ease of establishing the density of the prepared sample.

3. Method

A sample is prepared by compacting the bulk material under a selected weight or to a specific density condition of interest. The surface is penetrated by an annular cell with radial fins and a procedure followed to eliminate extraneous stresses acting normal to the surface of failure. From a null balanced position, a progressive torque load is applied to stress the sample until the sample fails, at which point a calibrated reading is noted of the force applicable at the point of yield. 4. Uses. Cohesion is a major failure property of interest relevant to the flow behavior of particulate solids. It is the yield strength possessed by the material in a specific state of compaction when no external load is acting normal to the failure surface. This affects the way in which the material will break away from the bulk in unconfined conditions, such as in the open outlets of hoppers and on the inclined surface of slopes.

Testing for cohesive strength has applications in many fields, including:

Research - Direct investigation of the cohesive strength of bulk solids.

Education - Illustrating the basic properties of solids and effect of compaction.

Material Specification - Quantifying material on a performance related basis and identifying of an effective parameter for storage and flow.

Classification - Relating property with reference sample or differing materials.

Categorisation - Comparing the material with dissimilar products to relate the behaviour or performance with other products of known behaviour or characteristics.

Significance Tests - To establish the effect of changes or variations of the materials specification with relation to flow properties.

Quality Control - To check the consistency of materials and their relationship to predetermined standards to ensure that the measured property falls within certain values.

Design - Supplements the 'Jenike' shear cell tests for the construction of powder yield loci as a basis for hopper design by providing a point on the zero applied stress axis through which the yield loci passes.