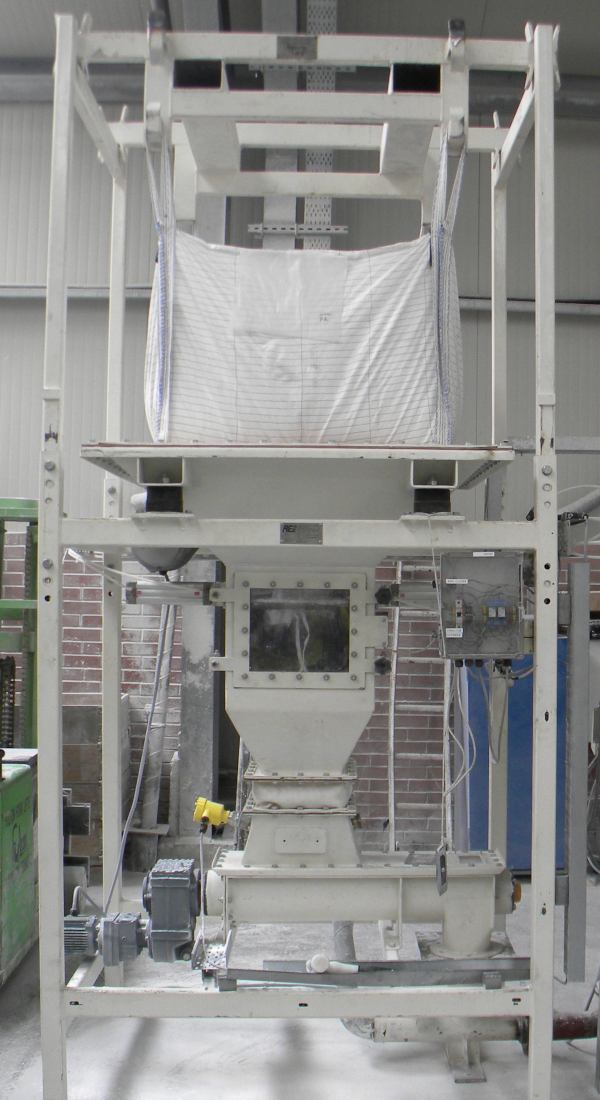

Big bag discharge stations for effective and reliable emptying of flexible IBCs including discharge aids and integral feeders for controlled feed rates.

44 (0)1204 386723

sales@ajax.co.uk

sales@ajax.co.uk

Customer

Testimonials

Testimonials

Products

Page

Page

Solid News

Newsletters

Newsletters

Company

Brochures

Brochures