Powder Testing for Flow

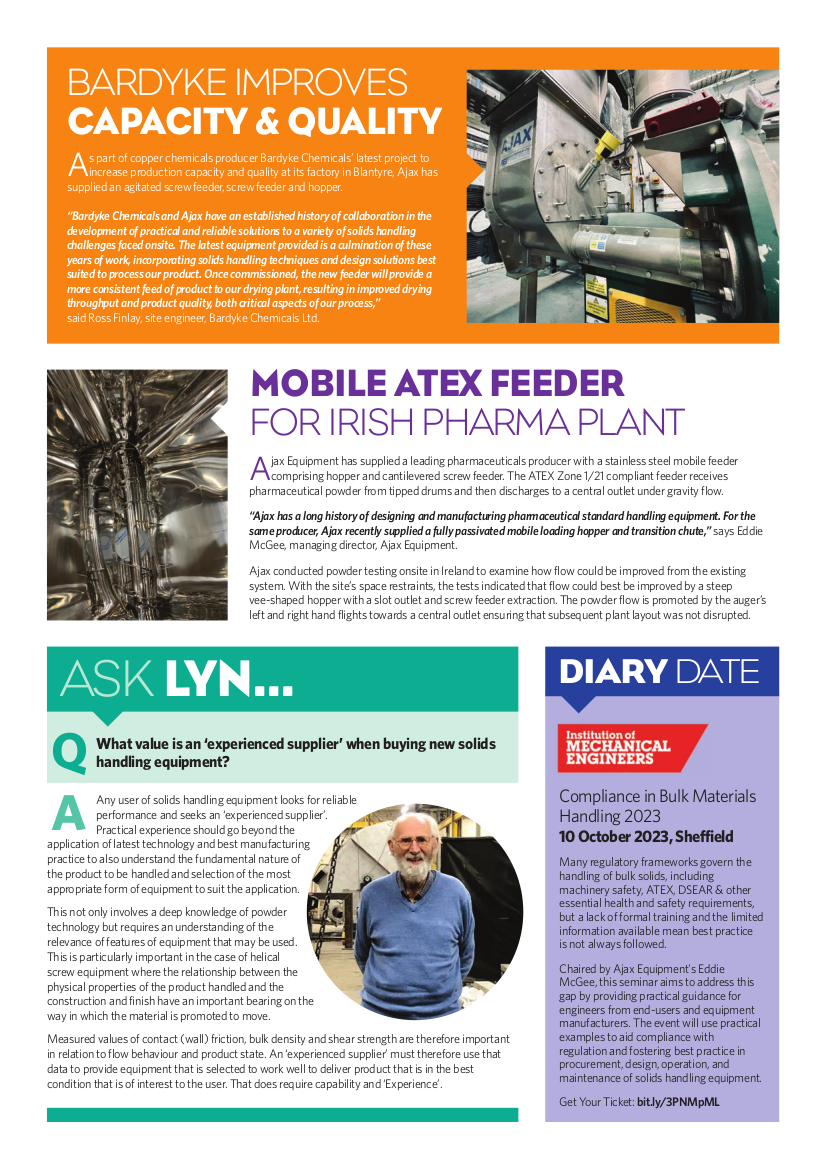

AJAX Multiple Powder Testing and Powder Test Equipment

The most important powder properties that determine bulk flow characteristics are: -

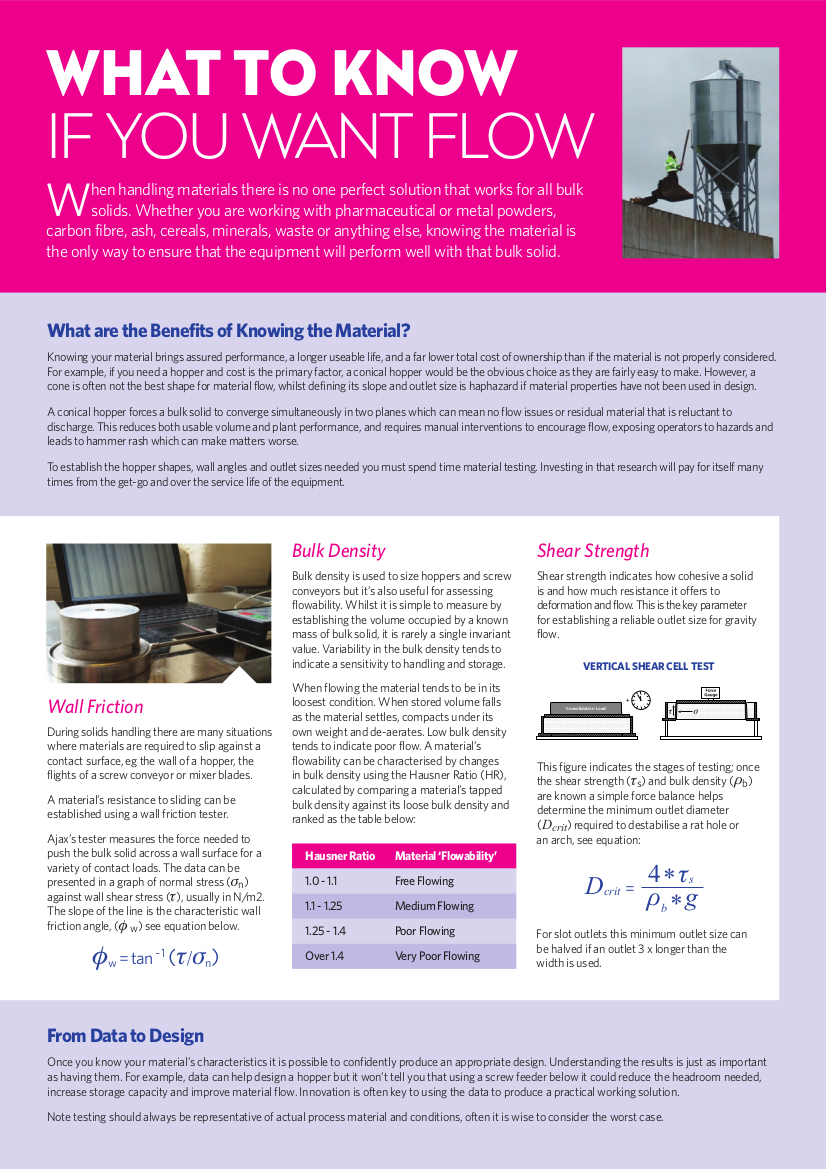

Bulk Density - This provides the driving force for gravity flow.

Wall Friction - Which determines the resistance to slip on a contact surface, for any given contact load.

Shear Strength - The feature that inhibits deformation of the bulk.

These properties do not have a single value for any particular bulk product, but depend upon the 'State' of the material, as formed by its stress history, and the current stresses that are acting on the bulk. For this reason, tests have to be related to conditions of interest and performed according to a relevant procedure. These measured values are essential for a quantitative approach to equipment design or quality control.

Tensile and Cohesive strength measurements indicate the nature of particle-to-particle attraction and transverse interference values. These testers are useful for rapid quality or comparative tests, compaction characteristics and for fundamental research into powder behaviour.

Density/Compaction tests provide an important guide to how a material will gain strength with change of density. This is used to assessing potential flow problems and give comparative values between similar or different bulk materials.

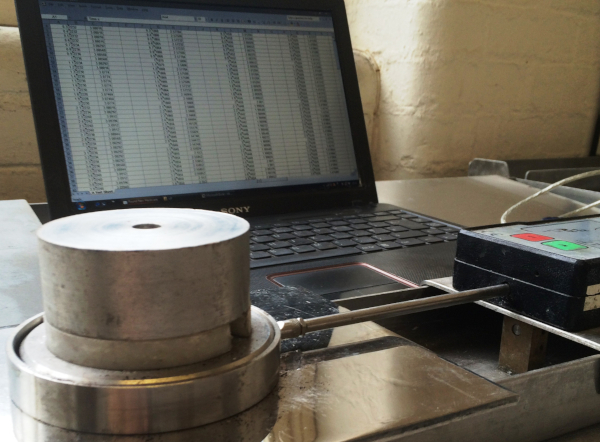

Wall Friction Tester for Hopper and Equipment Design

An important design parameter for solids storage and handling is how the material slips on surfaces of contact. This measurement is a dominant factor for determining the inclination of a hopper wall for the required mode of flow chute angles, mixer blades, screw feeders and conveyors are also dependant upon wall friction. This measurement further allows the selection of the most appropriate surface contact material or finish to be specified for a given duty. The Ajax wall friction device is a versatile instrument that is suitable for both laboratory and field work.

More Information

Vertical Shear Tester for Flow Evaluation

Bulk material flow characteristics are assessed from shear strength measurements. The Ajax Vertical Shear Strength Cell is used to measure the shear strength of the bulk solid in a specific condition of compaction. The design minimizes the effect of wall friction during compaction of the samples and provides sensitive conditions for measurement of the failure strength. The results reflect initial material failure conditions at the initiation of gravity flow and are used to indicate the size of the hopper outlet required for reliable discharge.

More Information

Tensile Tester for Quality Control and Research

Tensile strength is a fundamental, primary property of powder as it represents the inherent particle to particle attractive forces that develop when a mass of particles is compacted. The value provides a terminal point of the yield loci of failure for samples in given states of compaction. Different values apply according to the method in which the material is compacted and failed. The Ajax device measures the weakest mode of failure, as this is the key value of industrial interest, for example, the strength of tablets, agglomerates and compacted products. This compact device is robust, yet capable of measuring very delicate forces.

More Information

Annular Shear and Attrition Tester for Design, Flow and Particle Strength Evaluation

These devices follow the general form of the well-established Walker Cell, with the notable distinction that the side walls of the cell are driven with a rotational speed midway between the speed of the base and the stationary top surface. This feature counters the wall effect drawback of the original machine and more accurately reflects practical shearing conditions. As an Annular Shear Cell it is used to establish the flow function of a powder. The attrition cell version measures particle strength under varied conditions of loading and confined shearing.

More Information

Cohesion Tester for Flow Comparison and Quality Control

Cohesion is the yield strength possessed by a pre-compacted bulk solid when no external load is acting at right angles to the failure surface. This measurement indicates the way in which material will shear within the bulk in unconfined conditions, for example, indicating the stability on the surface of slopes and the forces necessary to move a blade through a static bed of product.

More Information

Compacted Density for evaluation of Stability and Predictability

The sensitivity of a bulk material to change of flow behaviour with settlement and compacting loads is brought out by the Ajax load/compaction device. This instrument measures the incremental change in density when a bulk material is subjected to a compacting stress. It extends density values from 'poured', 'settled' and 'tapped' density measurements, to give a broad picture of density conditions. It shows how its volume changes with time under a constant applied stress and is therefore a useful tool for the rapid evaluation of flow behaviour, characterisation and for examining the potential behavioural characteristics of bulk materials.

Please call AJAX on 44 (0)1204 386723 if you have an application for our powder test equipment or if you require a quotation for AJAX to perform powder testing on your behalf.

New Uploads and Featured Pages

Please Rate This Page

Thank You for providing your feedback. Please email AJAX Website Administrator if you have any additional comments regarding this web page.

X Close

X Close