Screw Elevators

AJAX Screw Elevators

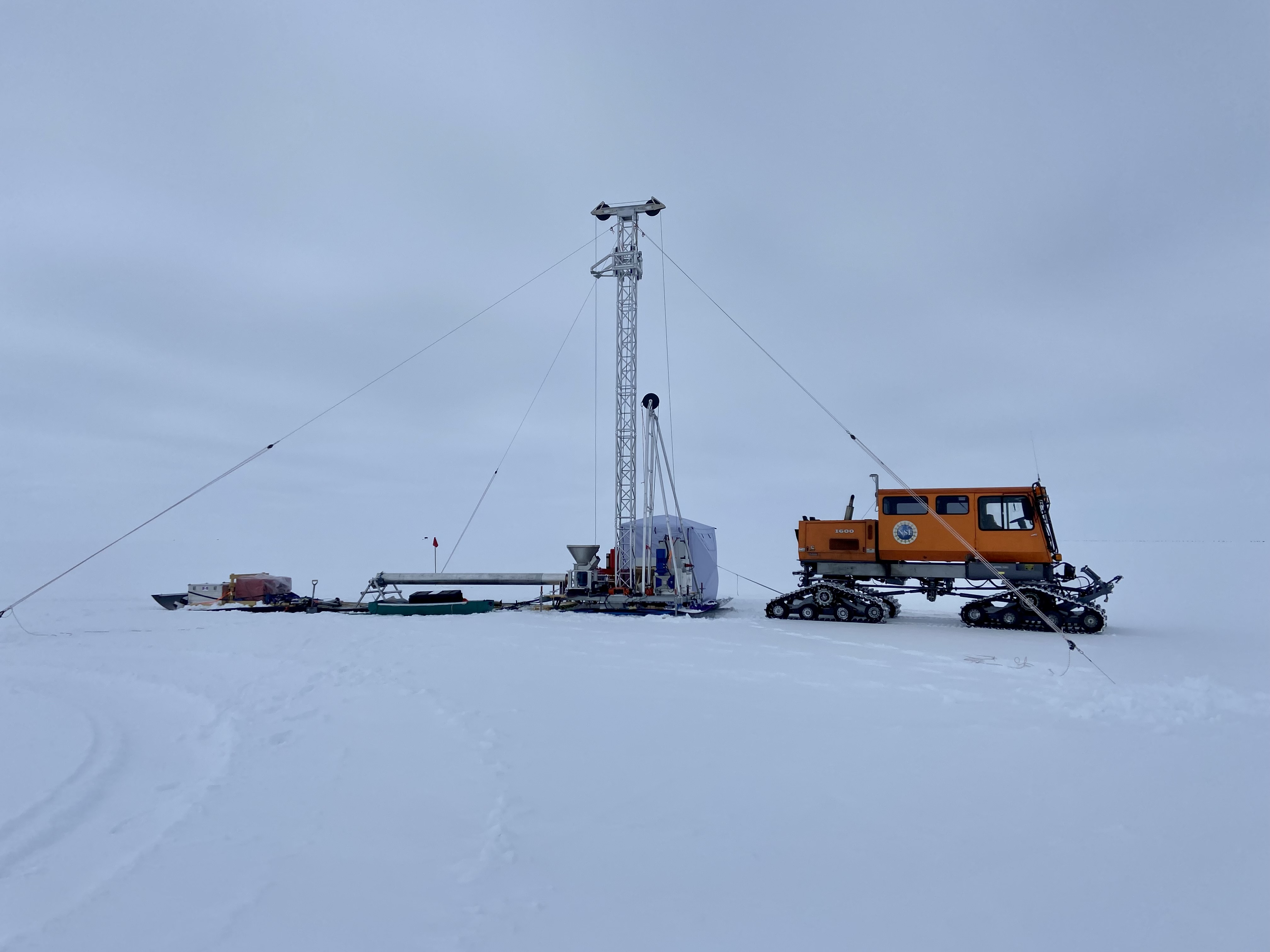

Ajax screw elevators are offered for a wide range of throughputs, product characteristics and site layout needs. Elevators differ from screw conveyors because the transfer dynamics are different for horizontal or shallowly inclined screws. Conveyors and feeders tend to 'push' material forwards with relatively low rotational speeds and moderate to high casing loading. Elevators however usually run at much higher rotational speeds and lower loading using a 'throwing' action to progress the material from flight pitch to flight pitch. In general the 'push' mode of conveying and feeding is acceptable for inclinations of up to 30 degrees above which the screw really needs to act like an elevator and operate in a 'throw' mode. Elevator performance like that of all handling equipment is highly material dependent.

Elevators can be designed to accept a flood feed and will need an infeed hopper correctly shaped for reliable flow. Sometimes a controlled feed into the elevator may be preferred and this is often a better option for reliable flow. Combined elevators and feeders by Ajax usually use a short cantilevered screw directly injecting the powder into the elevator to positively promote the flow. Casings for elevators tend to need either completely circular casings or be fitted with covers with an internal profile to match a circular section as this profile is needed to constrain the material and ensure efficient elevation without the powder flowing backwards as would be the case in a simple U shape too steeply inclined.

AJAX have produced elevators for all powder handling industries and for a vast range of materials including difficult to handle gels and filter cakes. As with all our product range, European Union directives such as PED and ATEX can be accommodated as required. AJAX also produce an elevator with a static screw and a rotating casing. This design is useful where the elevator needs to control the rate of feed and where large distances need to be spanned by a single screw. Please Click Here for more information on this type of screw elevator.

OPTIONAL EXTRAS

- Clean out doors.

- Fabricated in mild steel, stainless and high nickel alloys with a variety of finishes.

- Drive arrangements to suit individual requirements.

- Split Casings for easy cleaning.

- Chute or hopper style inlets.

- Mobile or fixed units.

- Dust extraction hoods.

- Jacketed construction suitable for steam or water.

See Also

New Mobile Screw Elevator Design from Ajax Equipment

Ajax Equipment supplies test rig for Wolfson Centre project

Ajax improve solid handling at Renewable Energy Technology

Please call AJAX on 44 (0)1204 386723 if you have a screw elevator application or want to know more about our screw elevators.

New Uploads and Featured Pages

Please Rate This Page

Thank You for providing your feedback. Please email AJAX Website Administrator if you have any additional comments regarding this web page.

X Close

X Close