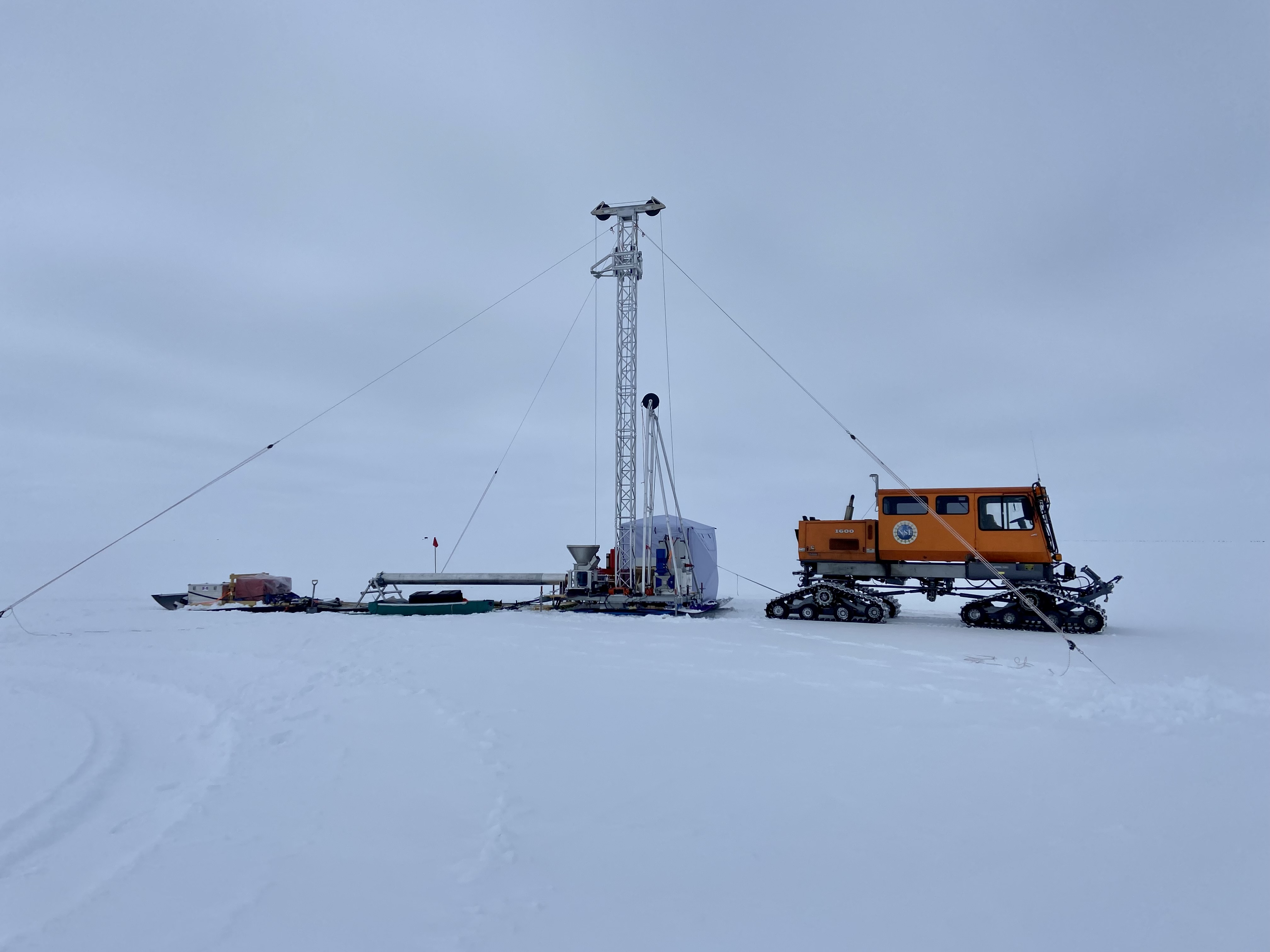

Screw Feeders for Ineos Fluor

Solids handling and processing equipment specialist, Ajax Equipment is supplying a screw feeder, screw conveyor and associated plant to INEOS Fluor's hydrofluorocarbon (HFC) production facility in Runcorn.

INEOS Fluor, the worlds leading manufacturer of HFC 134a, is expanding its production facility for hydrofluorocarbon 125, trade name KLEA 125 - a key constituent of efficient refrigerant blends used in air-conditioning systems. HFC refrigerants have enabled companies around the world to replace chlorofluorocarbons (CFCs) and hydro chlorofluorocarbons (HCFCs) that are being phased out under The Montreal Protocol on Substances that deplete the Ozone Layer.

The Ajax screw feeders and conveyor are part of a slaked lime feeding plant used to upgrade the effluent treatment facility for the new plant, providing significant new capacity.

"This is a significant project for INEOS Fluor, which secures the long term future of our business and meets the needs of refrigeration and air-conditioning companies world-wide. Ajax is a local supplier that we trust. Having worked with them in the past we are confident that they meet the high standard that we require if we are to successfully commission this project in time to meet our customers expectations", commented Justin O'Doherty, Manufacturing Manager, INEOS Fluor. Over 6 metres in length, the inclined 350mm screw feeder is designed to transfer lime to a slaker reaction vessel and a second reaction vessel via an Ajax screw conveyor. The feeder includes a specially designed screw auger enabling the smooth transfer of lime to either an intermediate outlet half way along the screw feeder or to the end of the feeder. The screw feeder is flighted so that carry over is prevented when the intermediate valve is opened.

The design helps to achieve high reliability; it also meets the requirement of an existing infrastructure and provides a degree of flexibility in the slaking operation.

The intermediate outlet allows lime to be dropped into the size 400mm screw conveyor supplying the second reaction vessel. Ajax has designed the outlet with a closely fitting slide valve with expanding sides to facilitate self-cleaning. This ensures any material in the valve is free to drop into the conveyor when the valve is opened, preventing hold-ups blockages that would affect the reliability and consistent performance of the unit.

For more information on Ajax’s screw Feeders, call +44 (0)1204 386723 or visit our

Screw Feeders page.