Click on an image to start slide show

X

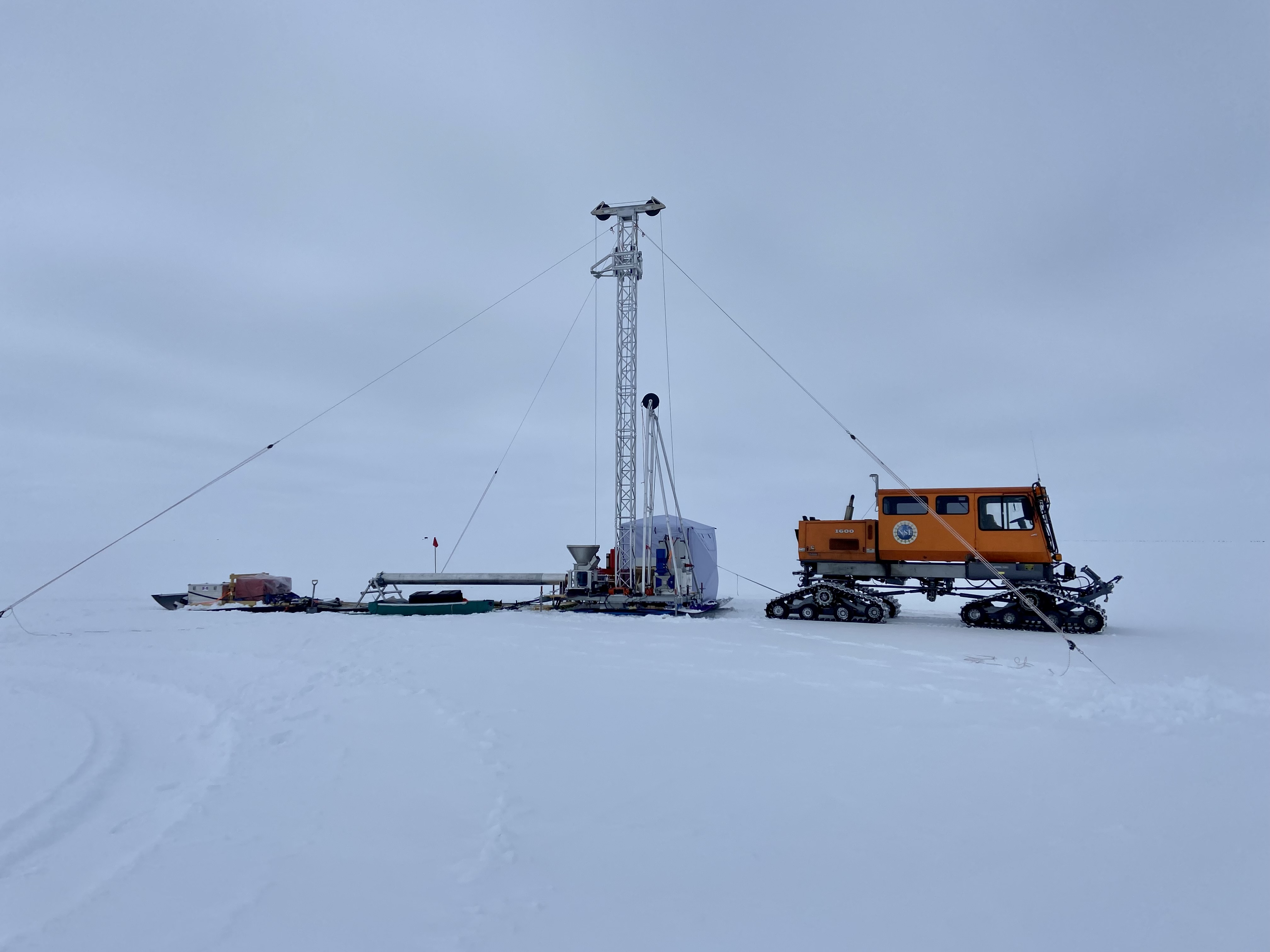

Bradley Pulverizer Hopper and Feeder

Solids handling specialist, Ajax Equipment, has supplied mineral processing equipment company, Bradley Pulverizer, with a twin screw feeder for handling phosphate at an Egyptian processing plant. In addition, Ajax has supplied designs for a hopper and flow insert to prevent 'rathole' formation, and encourage mass flow, in a hopper containing the phosphate powder.

Handling a powder, such as phosphate, with highly variable flow properties can be challenging. The state of the material can change in reaction to various factors including composition, temperature, residence time and consolidating pressures in the hopper.

Undertaking powder testing allowed Ajax to determine the hopper wall inclination needed for phosphate powder mass flow, to increase the mean residence time of the hopper contents, and enhance de-aeration. Ajax recommended replacement of the bottom section of the hopper, and designed a hopper insert to promote flow. Meanwhile the twin screw feeder's extraction geometry ensures material is drawn from the full width and length of the new hopper outlet.

Ian Hancock, operations manager at Bradley Pulverizer, commented on the project, 'From the high standard equipment supplied it is clear that Ajax understood our process and what we wanted to achieve. Working with Ajax's technical director Eddie McGee on the IMechE's Bulk Handling Committee I knew Ajax had experience of the flow issues occurring. Since the equipment has been installed the performance of the process has significantly improved; by providing complete control over the flow of phosphate powder Ajax's equipment has allowed us to produce the high quality product desired'.

Describing the equipment Ajax Equipment technical director, Eddie McGee, said, 'Using powder testing and Bradley Pulverizer's feedback on the process, Ajax Equipment devised a system design which would work with the material and current equipment to enhance material flow. It would be expensive to convert the entire hopper to mass flow as this would impose structural and equipment changes to other parts of the process. By considering the modifications necessary to secure reliable operating performance Ajax was able to design equipment which fitted within the production line while minimising process disruption.'

For more information on AJAX's screw feeders please visit our

Screw Feeder Page or call AJAX on 44 (0)1204 386723.